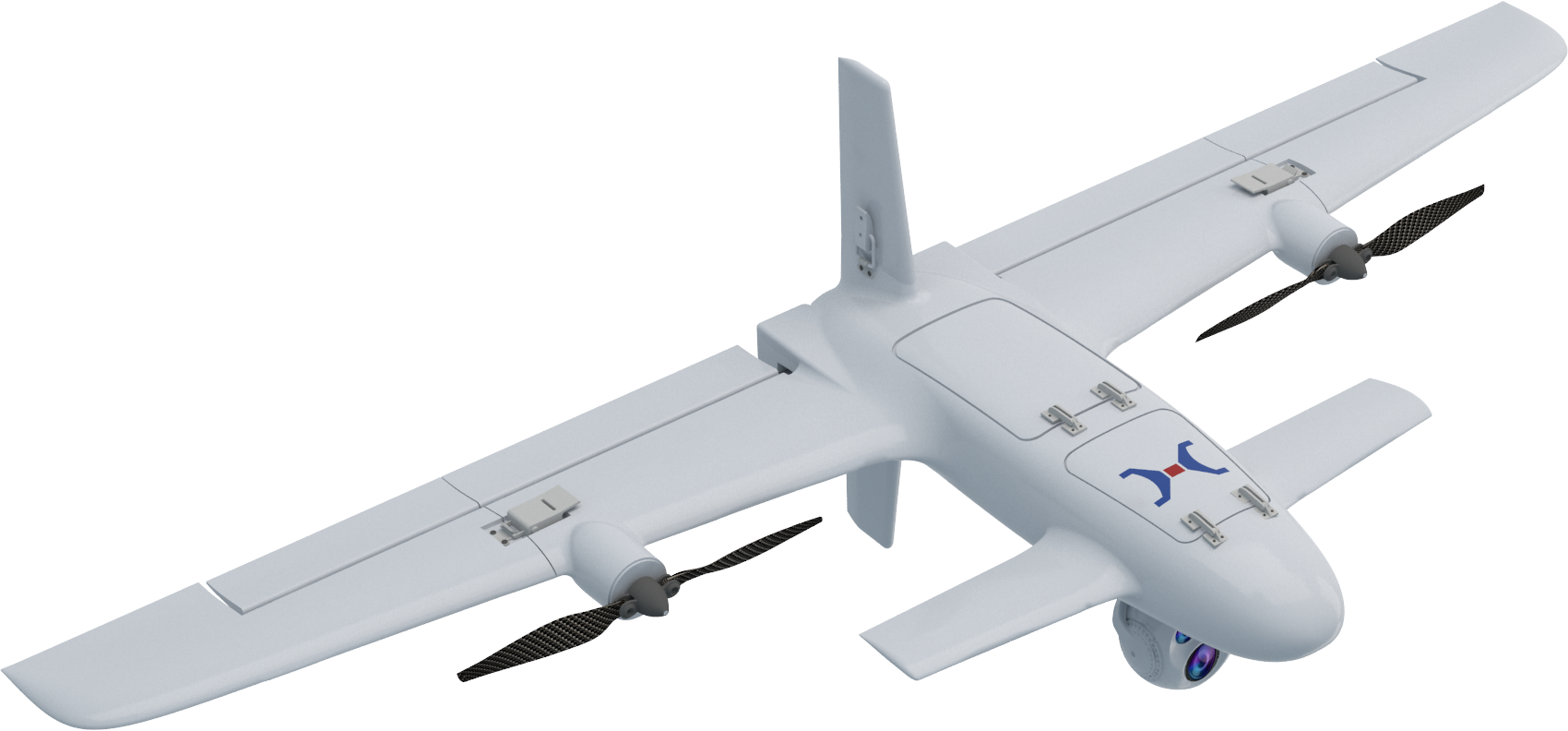

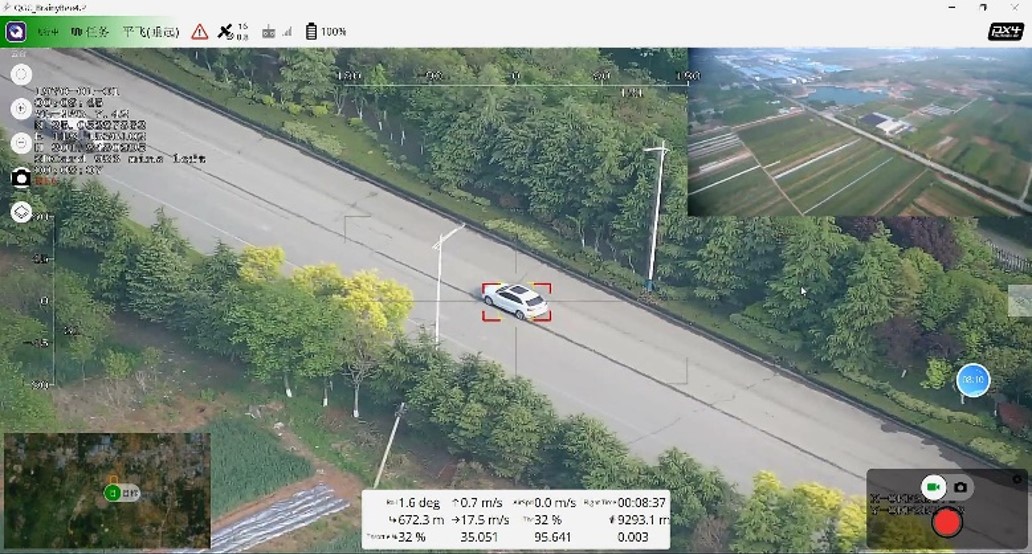

Efficient Inspections – Drones quickly cover vast areas, transmitting high-definition images and precise data in real-time, significantly improving inspection efficiency.

Safe Operations – No need for personnel to enter hazardous areas, reducing safety risks and ensuring the protection of inspection staff.

Accurate Monitoring – Equipped with high-definition imaging, infrared thermal imaging, and laser detection devices, drones accurately identify pipeline leaks, equipment failures, and other hazards.

Rapid Response – In emergencies, drones swiftly reach the scene, providing real-time images and location data to support quick decision-making.

All-Weather Operations – With thermal imaging and high-resolution cameras, drones can operate efficiently at night or in adverse weather conditions.

Intelligent Analysis – Using smart recognition and big data analysis, drones automatically alert to anomalies, enhancing inspection accuracy and decision-making efficiency.

Low Inspection Efficiency – Traditional manual inspections are slow, with limited coverage, making it hard to meet the high-efficiency inspection demands of large-scale oilfields.

Safety Hazards – The complex oilfield environment poses risks such as high temperatures, high pressure, and toxic gases for inspectors.

Inaccurate Data Collection – Traditional methods struggle to provide real-time, precise inspection data, leading to high rates of missed or false detections.

Slow Emergency Response – In the event of emergencies, traditional inspection methods cannot quickly reach the site, delaying timely action.

Difficulty in Night and Harsh Weather Operations – Traditional methods are inefficient at night or under adverse weather conditions, affecting task execution.

Low Automation, Reliance on Manual Image Recognition – Image data requires manual visual analysis, which is slow and prone to missed or false detections.